Related resources

- For more information on the XLBatch and XLBatchReports concrete batch control systems, please see this flyer.

- For a pump panel quote, please send an e-mail to Michael Hampson.

Get Adobe Acrobat Reader Here.

Products and Services

XL Automation provides products and services on a per-project or on a T&M basis, depending on the specific work requirements and customer preferences. We can provide both large and small solutions, from single on-site or remote analysis or troubleshooting service, to large integration jobs including both mechanical and electrical components. We also provide contract maintenance service both for our own installed base as well as for existing systems in your plant. Below are some examples of past and existing products and services.

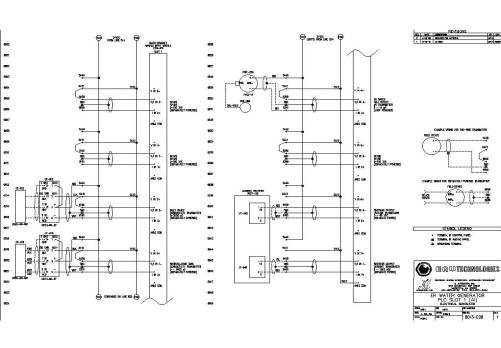

The heart of a successful control sytem is a solid design utilizing

appropriate components and straightforward programming. XL

Automation uses AutoCAD for electrical engineering drawings and has

an extensive library of component blocks covering a wide range of

manufacturers, resulting in quicker concept-to-finish drawing

packages.

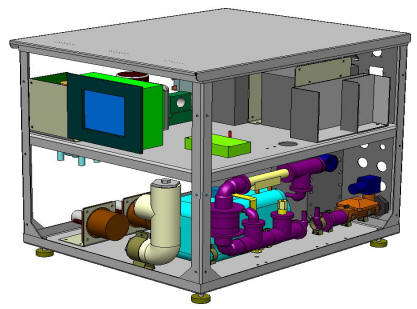

XL Automation prefers SolidWorks and AutoCAD 3D for mechanical

design, modeling, and detailing. Above is an example of a rendered

3D model of a desktop electrolyzed water generator used in the

cleaning/sanitation/drinking water industry.

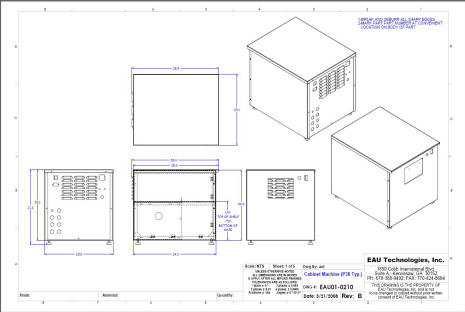

Accurate mechanical detail drawings are a key component of

successful fabrication.

XL Automation also has a standard design for motor starter panels

that are often used for independent control of fans, pumps,

lighting, and other loads. We would be happy to quote a standard

starter panel for you at any time.

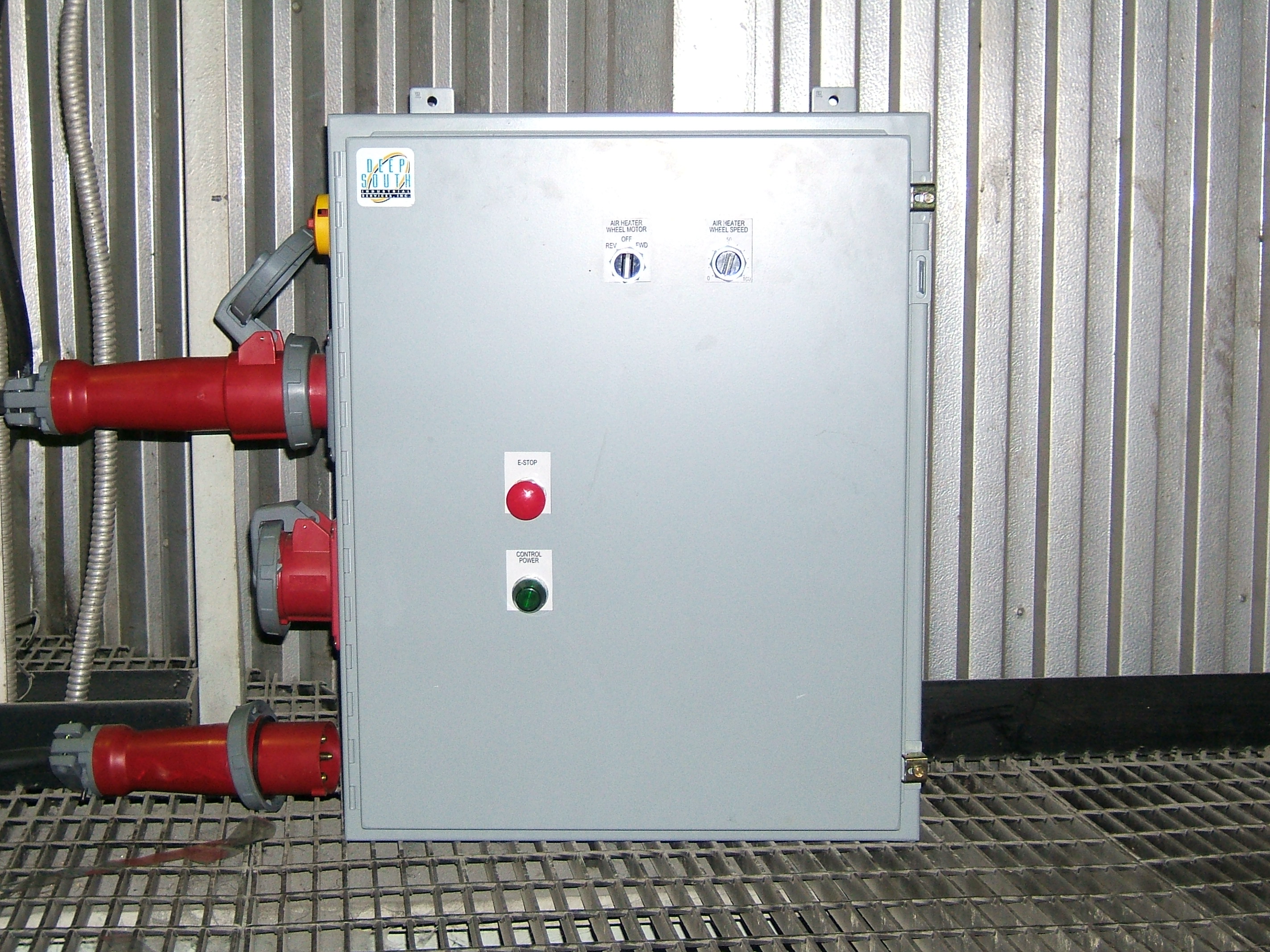

25HP Drive and control for an air preheater drive motor, used for

industrial cleaning the air preheater honeycomb in power plants.

Remote I/O control panel connected to distributed I/O control

system with an Omron PLC Master and Profibus I/O networking. Also

contains a Yaskawa servo drive for motion control on a Mechatrolink

network.

Remote I/O control panel connected to distributed I/O control

system with an Omron PLC Master and Profibus I/O networking. Also

contains a Yaskawa servo drive for motion control on a Mechatrolink

network.

The above photo was taken during a factory acceptance test of an

unwind/rewind wash system for metal foil. The custom designed and

fabricated (by XL Automation) unwind/rewind stands were integrated

with an existing wash system provided by ChemCut Corporation. The

unwind/rewind stands utilize Allen-Bradley ControlLogix PAC control,

PowerFlex 700 VFDs, and Ethernet Flex I/O.